ABOUT DUCTEASI

What is

DUCTEASITM

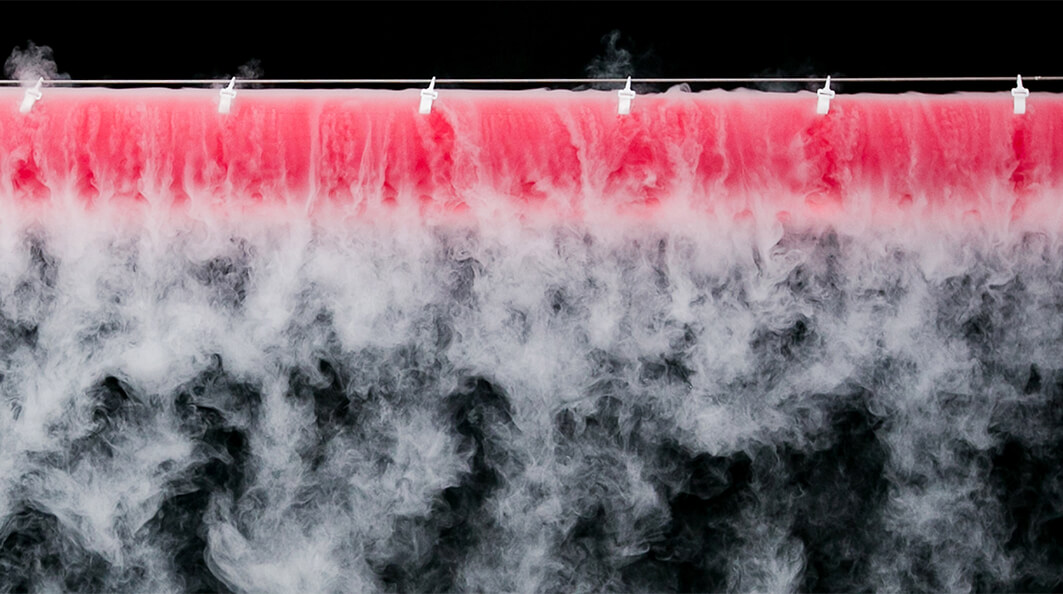

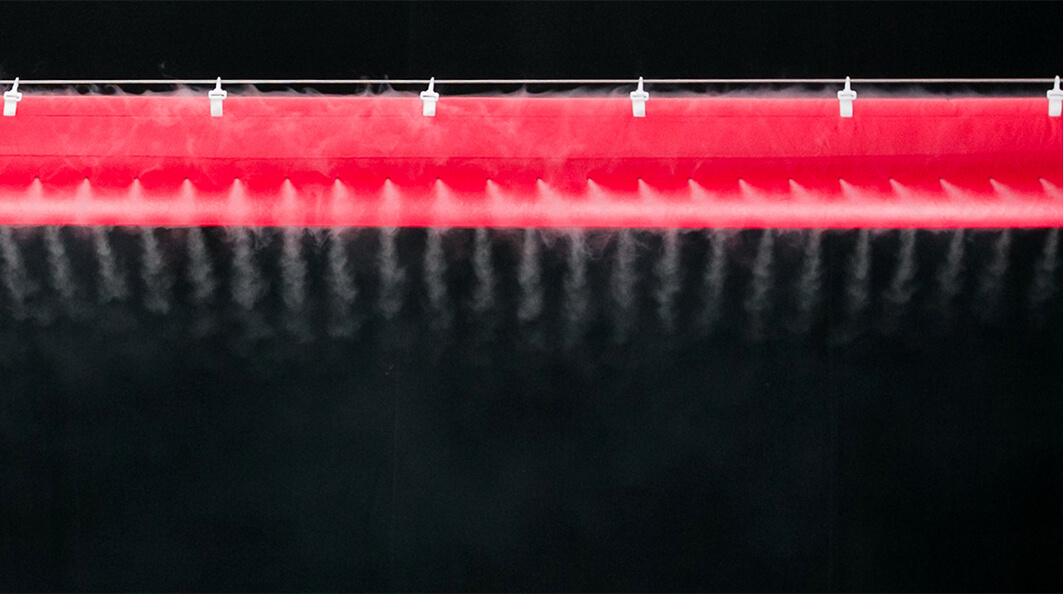

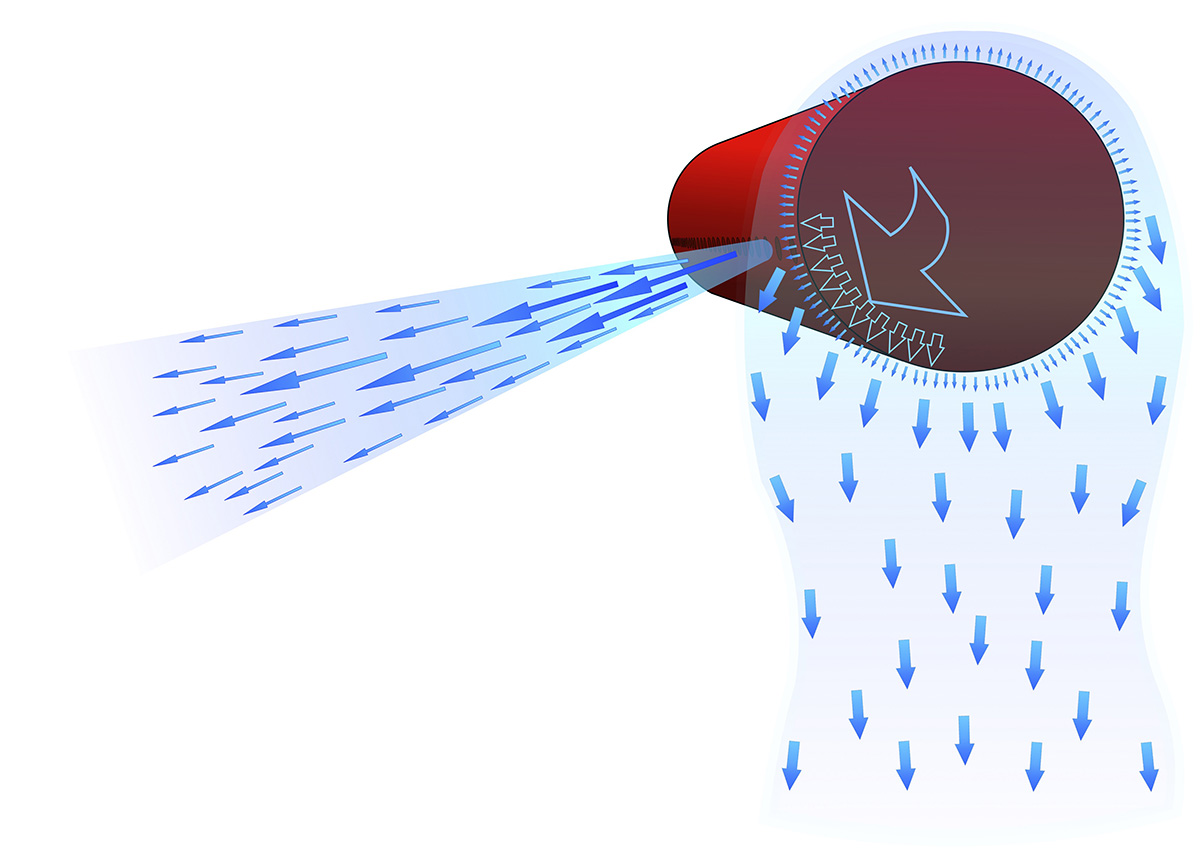

When fan is turned on, the internal static pressure inside the fabric duct increases. Fabric duct is inflated to a circular shape when the air pressure acts on the fabric surface. Micro-perforation on the fabric allows cold air to leak out and covers the entire fabric ducting (preventing condensation). The heavier cold air diffuse and displaces when mix with the room air. Control air jet laser cutting holes can be added on the fabric allowing long throw.

• Function – Transfer, balance and distribute conditioned air

• Material – Light weight fabric material

• Construction – Sewed to form circular shape join together using zippers

• Installation – Pre-fabricated and assemble on site using wires or rails support

• Aesthetic – uniform, soft surface with colour options

Design principle of fabric ducting air jet

No control air jets – for displacement cooling

Small holed control air jets – for low draught